For lithium ion batteries, the cathode materials that can be used should meet the characteristics of large reversible capacity, high potential and stability, non-toxic and low production cost. At present, lithium iron phosphate is the most common cathode material for lithium ion batteries. However, LiFePO4 has poor electrical conductivity and low lithium ion mobility. If LiFePO4 material is combined with graphene, its conductivity and multiplier performance can be improved theoretically.

目前分類:未分類文章 (135)

- Aug 23 Fri 2019 18:00

Application of graphene in cathode materials

- Aug 23 Fri 2019 17:58

Introduction to the graphene materials

Introduction to the graphene materials

Graphene Oxide is a two-dimensional planar nanomaterial composed of carbon atoms with a hexagonal honeycomb lattice,the c-c bond length is 0.141nm, the theoretical density is about 0.77mg/m2, and the thickness is only about the diameter of a carbon atom. Carbon atoms participate in hybridization in the way of sp2, and electrons can smoothly conduct between layers, so graphene conducts electricity extremely well. It is the material with the smallest resistivity known, which is one of the reasons why graphene has a promising future in batteries.

- Jun 14 Fri 2019 18:40

Metalized Cast Polypropylene (CPP) Films Quality Control

Metalized Cast Polypropylene (CPP) Films CPP films are transparent cast polypropylene films designed to offer high performance, great appearance and easy converting for flexible packaging and other applications.

- Apr 19 Fri 2019 15:46

How to Get Good Coating Effect When Making Lithium ion Battery

The Electrode Coating Machine is the key equipment for the production of lithium battery electrode. Because it directly affects the subsequent rolling operation, and even affects the performance of the entire battery. At present, the mainly lithium battery electrode coating process is: scraper type, roll to roll transfer coating type and a slit extrusion type. General speaking, laboratory equipment adopts the scraper type, the 3C battery adopts the roll to roll transfer coating type, and the power battery adopts the slit extrusion type.

- Apr 02 Tue 2019 16:51

Lithium battery cathode material

The main components of lithium ion battery include cathode, cathode, electrolyte, membrane, etc. The storage and release of lithium ion energy is realized in the form of REDOX reaction of electrode materials, and the cathode active material is the most critical core material of lithium ion battery.

Professor GOODENOUGH, the father of lithium battery, has made a great contribution to the research of lithium battery cathode materials. In 1980, while working at the university of Oxford in the United Kingdom, he discovered that lithium cobalt oxide (LCO) could be used as a lithium cathode. In 1981, he mentioned the feasibility of lithium nickelate (LiNiO2, also known as LNO) as a cathode material in the LCO patent. In 1983, he made his first attempt to use lithium manganate (LMO) as a cathode material for lithium-ion batteries. In 1997, he developed lithium iron phosphate (LiFePO4, or LFP), which is the cathode material of olivine structure. In addition, to solve the problem of unstable properties of lithium nickelate, a large amount of research has been conducted in the area of doping modification by Prof. DAHN from Canada and Prof. Sumika kosuki from Japan. In 1997, toda applied for the first patent of lini1-x-ycoxalyo2 (NCA). In 1999, liu zhaolin and yu aishui et al. from the university of Singapore introduced Mn modification on the basis of lithium ni-co (lini1-x-ycoxmnyo2, namely ternary material and NCM).

- Apr 02 Tue 2019 16:49

PVDF binder for Li-ion battery electrodes

Introduction:

Polyvinylidene fluoride binder(PVDF) is currently the most commonly used oil binder in the lithium ion battery industry. It is a non-polar chain polymer binder. It is characterized by strong oxidation resistance, good thermal stability and easy dispersion. N-methylpyrrolidone (NMP) is required as a solvent. This solvent has a high volatilization temperature, has a certain environmental pollution, and is expensive.

- Mar 27 Wed 2019 14:53

AC03 Desktop Light Fastness Tester’ use precautions

1. Do not install the Desktop Light Fastness Test Chamber unit near other heavy machinery.

- Feb 01 Fri 2019 16:22

The performance characteristics of vacuum drying oven

The vacuum drying oven is designed for drying heat sensitive, easily decomposable and easily oxidizable materials. It can be filled with an inert gas, which can make some ingredients with complex ingredients dry quickly.

Scope of application:

Scope of application:

- Jan 03 Thu 2019 08:58

High-voltage Resistant Electrolyte

Although high-voltage lithium battery materials are getting more and more attention, these high-voltage anode materials are still unable to achieve good results in practical production and application. The biggest limiting factor is that the electrochemical stability window of the carbonate-based electrolyte is low. When the battery voltage reaches about 4.5(vs.Li/Li+), the electrolyte begins to produce violent oxidation decomposition, causing the lithium-intercalation and lithium-deintercalation for the battery not working properly. The development of electrolytic liquid systems that can withstand high voltage is an important step to promote the application of this new material.

- Dec 29 Sat 2018 15:46

High Temperature Resistant Battery Separator

The battery separator plays a major role in lithium ion battery conduction lithium ions and isolation between the positive and negative electrode electronic contact. It is an important component to support the battery to complete the electrochemical process of charge and discharge.

- Dec 17 Mon 2018 16:17

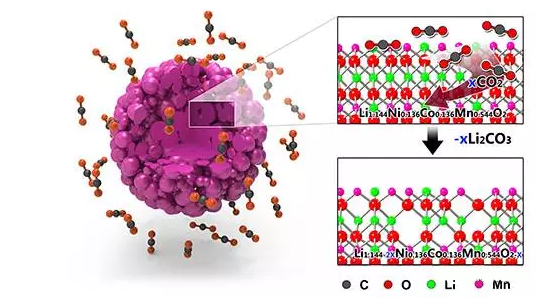

High voltage and high capacity lithium-rich material

The lithium-rich manganese-based (xLi[Li1/3-Mn2/3]O2; (1–x) LiMO2, M is a transition metal 0≤x≤1, and the structure is similar to LiCoO2) has a high discharge specific capacity. It is about twice the actual capacity of the cathode material currently used, and is therefore widely studied for lithium battery materials. In addition, since the material contains a large amount of Mn element, it is more environmentally safe and cheaper than LiCoO2 and the ternary material Li[Ni1/3Mn1/3Co1/3]O2. Therefore, xLi[Li1/3-Mn2/3]O2; (1–x) LiMO2 material is considered by many scholars as the ideal material for the next generation of lithium ion battery cathode materials.

- Nov 26 Mon 2018 10:40

High capacity silicon-carbon anode

As an important component of lithium ion battery, negative electrode material has a direct impact on the energy density, cycle life and safety performance of the battery and other key indicators. Silicon is the anode material of lithium ion battery with the highest specific capacity (4200mAh/g) known at present. However, due to its over 300% volume effect, The silicon electrode material will pulverize during charging and discharging, and flake off from the collector fluid. caused the loss of electrical contact between active matter and active matter, the active matter, and the stream of fluid, and forming a new layer of solid electrolyte layers, which ultimately leads to the deterioration of electrochemical properties. In order to solve this problem, researchers have made a lot of explorations and attempts, among which silicon-carbon composites are very promising materials.

- Nov 19 Mon 2018 16:28

High energy density ternary material battery

With the pursuit of energy density of battery, the ternary anode materials (generally referred to as layered lithium NCM nickel cobalt manganate materials) have attracted more and more attention. The ternary anode material has the advantages of high specific capacity, good recycling performance and low cost. By increasing the voltage of the battery and the content of nickel in the material, the energy density of the ternary positive electrode material can be effectively improved.

Theoretically, the ternary material itself has the advantage of high voltage. The standard test voltage of the ternary positive electrode material is 4.35v, under which the ordinary ternary material can show excellent cyclic performance. The charging voltage is increased to 4.5v, and the capacity of the symmetrical materials (333 and 442) can reach 190, which is also good for circulation, while 532 is not so good. When the charge reaches 4.6v, the circulability of the ternary material begins to decline, and the flatness becomes more and more serious. At present, it is difficult to find matching electrolyte with high voltage anode material.

Theoretically, the ternary material itself has the advantage of high voltage. The standard test voltage of the ternary positive electrode material is 4.35v, under which the ordinary ternary material can show excellent cyclic performance. The charging voltage is increased to 4.5v, and the capacity of the symmetrical materials (333 and 442) can reach 190, which is also good for circulation, while 532 is not so good. When the charge reaches 4.6v, the circulability of the ternary material begins to decline, and the flatness becomes more and more serious. At present, it is difficult to find matching electrolyte with high voltage anode material.

- Nov 02 Fri 2018 16:45

The reason for choosing a thermal mass flowmeter and its application range

You have eight reasons to choose it!

● Without temperature and pressure compensation, the mass flow of gas is measured directly!

- Nov 02 Fri 2018 16:40

All-Solid-State Lithium-ion Battery

The electrolyte of the current commercialized lithium-ion battery is liquid, so it is also called liquid lithium-ion battery. In simple terms, all- solid-state lithium-ion battery refers to the battery structure in which all components are in solid form, replacing the traditional lithium ion battery's liquid electrolyte and diaphragm with solid electrolyte.

Compared with liquid lithium-ion batteries, all-solid electrolyte has the following advantages:

Compared with liquid lithium-ion batteries, all-solid electrolyte has the following advantages:

- Oct 12 Fri 2018 15:27

How to improve the safety of electrolyte

High reactivity exists between electrolyte and positive and negative electrodes, especially at high temperature. To improve the safety of battery, improving the safety of electrolyte is one of the effective methods. The potential safety risks of electrolyte can be effectively solved by adding functional additives, using new lithium salts and using new solvent.  According to the different functions of additives, they can be divided into the following: safety protection additives, film forming additives, protection positive electrode additives, stable lithium salt additives, lithium precipitating additives, fluid anti-corrosion additives, and enhancement of infiltration additives.

According to the different functions of additives, they can be divided into the following: safety protection additives, film forming additives, protection positive electrode additives, stable lithium salt additives, lithium precipitating additives, fluid anti-corrosion additives, and enhancement of infiltration additives.

In order to improve the performance of commercial lithium salts, the researchers have replaced them with atoms and obtained many derivatives. Among them, compounds obtained by substituting atoms with perfluoroalkyl groups have many advantages, such as high flash point, approximate electrical conductivity and enhanced water resistance. In addition, the anionic lithium salts obtained by chelating boron atom with oxygen ligand have high thermal stability.

- Sep 30 Sun 2018 15:37

High nickelic ternary material is an irresistible trend,When will the NCM811 era come?

With the continuous development of the three-element battery technology market, the shortage of Lithium, Cobalt and other resources is brought. In particular, the small supply flexibility of cobalt itself, and if mainstream manufacturers choose the route of NCM622, it will lead to a serious shortage of cobalt supply, which will force the new energy vehicle enterprises to develop towards the route of NCM811.

Since last year, the requirement for energy density of new energy vehicle power batteries has been increasing due to the increasing demand for mileage. Especially in China, the subsidy standard is directly linked to energy density, and the path of ternary material has become the common choice of mainstream battery enterprises. At the same time, with the price rise caused by the shortage of raw materials such as Cobalt metal, high Nickel ternary gradually becomes the development trend of power battery.

- Sep 28 Fri 2018 17:18

Control System Of A Gensets

An electronic control system has been designed and installed to control and monitor the generator set. Depending on the requirements of the Diesel generator set, one of several different standard control systems may be fitted. Other more specialised systems may be fitted for specific installations in which case separate documentation is provided.These control systems consist of three major components working together:

Control Panel – provides a means of starting and stopping the generator set, monitoring its operation and output and automatically shutting down the generator set in the event of a critical condition arising such as low oil pressure or high engine coolant temperature to prevent major damage to the engine / alternator.

- Sep 21 Fri 2018 15:49

The pouch battery market expansion on the industry impact

Driven by the core goal of high energy density and high battery life, the penetration rate of pouch battery in the new energy vehicle market is gradually accelerating. It is estimated that 13.4 billion yuan of special equipment needs of pouch battery will be derived by 2020 based on the expansion demand of various battery manufacturers.

As the core technology of pouch battery manufacturing, the lamination machine market has attracted many equipment manufacturers to seize the layout. Traditional brands with deep industry accumulation are accelerating the process improvement, further improving the efficiency of lamination process and the degree of integration automation.

- Sep 14 Fri 2018 17:10

High nickel Material NCM 811 trends drive equipment upgrades

According to China's goal of achieving power battery energy density of 300Wh/kg by 2020, it is inevitable that the material combination form of NCM 811/nca with silicon-carbon anode is adopted.

In the first half of this year, the application of NCM 811/NCA materials in the power battery market gradually increased. As the core equipment technology of high nickel anode materials involves upgrading and adjustment, the production process control is more strict than that of conventional anode materials, which drives the technical upgrade of material equipment manufacturers. In general, the core equipment that high nickel anode materials enterprises need to upgrade and replace mainly includes: furnace, drying equipment, crushing equipment, grinding machine, dehumidification equipment, etc.

In the first half of this year, the application of NCM 811/NCA materials in the power battery market gradually increased. As the core equipment technology of high nickel anode materials involves upgrading and adjustment, the production process control is more strict than that of conventional anode materials, which drives the technical upgrade of material equipment manufacturers. In general, the core equipment that high nickel anode materials enterprises need to upgrade and replace mainly includes: furnace, drying equipment, crushing equipment, grinding machine, dehumidification equipment, etc.