For lithium ion batteries, the

cathode materials that can be used should meet the characteristics of large reversible capacity, high potential and stability, non-toxic and low production cost. At present, lithium iron phosphate is the most common cathode material for lithium ion batteries. However, LiFePO4 has poor electrical conductivity and low lithium ion mobility. If LiFePO4 material is combined with graphene, its conductivity and multiplier performance can be improved theoretically.

Due to the particularity of

graphene materials, relatively little research has been done on the cathode graphene materials. Studies have shown that when graphene is directly coated on the surface of LiFePO4 by hydrothermal method, the multiplier performance of composite materials is not very good. The reason may be the stacking or destruction of graphene material structure.

tobmachine 發表在 痞客邦 留言(0) 人氣(1)

Introduction to the graphene materials

Graphene Oxide is a two-dimensional planar nanomaterial composed of carbon atoms with a hexagonal honeycomb lattice,the c-c bond length is 0.141nm, the theoretical density is about 0.77mg/m2, and the thickness is only about the diameter of a carbon atom. Carbon atoms participate in hybridization in the way of sp2, and electrons can smoothly conduct between layers, so graphene conducts electricity extremely well. It is the material with the smallest resistivity known, which is one of the reasons why graphene has a promising future in batteries.

Battery Graphene materials have excellent thermal conductivity, and their theoretical room temperature thermal conductivity of single layer is up to 3,000-5,000w/(m*K). This property can be used to study the heat dissipation during battery operation.It has excellent mechanical properties and is a material with excellent toughness and strength, which can be used to develop and study flexible electrode materials. In addition, the high specific surface area and high transmittance of graphene are also of great research value.

XIAMEN TOB NEW ENERGY is a technology company focused on the lithium battery equipment research and development and material improvement. We can provide high-quality products and the most professional technical services.

tobmachine 發表在 痞客邦 留言(0) 人氣(0)

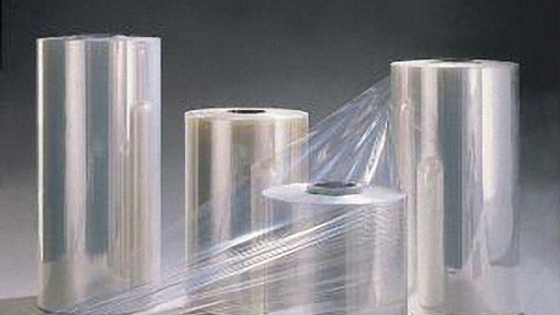

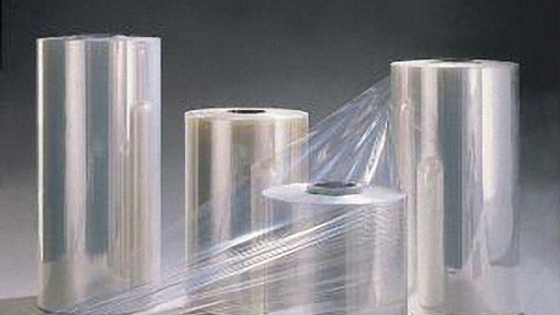

Metalized Cast Polypropylene (CPP) Films CPP films are transparent cast polypropylene films designed to offer high performance, great appearance and easy converting for flexible packaging and other applications.

tobmachine 發表在 痞客邦 留言(0) 人氣(39)

The

Electrode Coating Machine is the key equipment for the production of lithium battery electrode. Because it directly affects the subsequent rolling operation, and even affects the performance of the entire battery. At present, the mainly lithium battery electrode coating process is: scraper type, roll to roll transfer coating type and a slit extrusion type. General speaking, laboratory equipment adopts the scraper type, the 3C battery adopts the roll to roll transfer coating type, and the power battery adopts the slit extrusion type.

Scraper coating: the foil substrate passes through the coating roller and directly contacts the slurry trough, and the excess slurry is coated on the foil substrate. The gap between the blade and the foil substrate determines the coating thickness, then the surface of the material forms a uniform coating.

tobmachine 發表在 痞客邦 留言(0) 人氣(1)

The main components of lithium ion battery include cathode, cathode, electrolyte, membrane, etc. The storage and release of lithium ion energy is realized in the form of REDOX reaction of electrode materials, and the cathode active material is the most critical core material of lithium ion battery.

Professor GOODENOUGH, the father of lithium battery, has made a great contribution to the research of lithium battery cathode materials. In 1980, while working at the university of Oxford in the United Kingdom, he discovered that

lithium cobalt oxide (LCO) could be used as a lithium cathode. In 1981, he mentioned the feasibility of lithium nickelate (LiNiO2, also known as LNO) as a cathode material in the LCO patent. In 1983, he made his first attempt to use

lithium manganate (LMO) as a cathode material for lithium-ion batteries. In 1997, he developed

lithium iron phosphate (LiFePO4, or LFP), which is the cathode material of olivine structure. In addition, to solve the problem of unstable properties of lithium nickelate, a large amount of research has been conducted in the area of doping modification by Prof. DAHN from Canada and Prof. Sumika kosuki from Japan. In 1997, toda applied for the first patent of lini1-x-ycoxalyo2 (NCA). In 1999, liu zhaolin and yu aishui et al. from the university of Singapore introduced Mn modification on the basis of lithium ni-co (lini1-x-ycoxmnyo2, namely ternary material and NCM).

tobmachine 發表在 痞客邦 留言(0) 人氣(0)

Introduction:

Polyvinylidene fluoride binder(PVDF) is currently the most commonly used oil binder in the lithium ion battery industry. It is a non-polar chain polymer binder. It is characterized by strong oxidation resistance, good thermal stability and easy dispersion.

N-methylpyrrolidone (NMP) is required as a solvent. This solvent has a high volatilization temperature, has a certain environmental pollution, and is expensive.

Obvious deficiencies include:

1) Young's modulus is relatively high, between 1-4GPa, the flexibility of the pole piece is not good enough;

2) When PVDF absorbs water, the molecular weight decreases and the viscosity becomes poor, so the humidity requirement for the environment is relatively high;

3) For ion and electronic insulation, there is a certain degree of swelling in the electrolyte. It reacts exothermically with lithium metal and LixC6 at higher temperatures, which is detrimental to the safety of the battery.

tobmachine 發表在 痞客邦 留言(0) 人氣(14)

1. Do not install

the Desktop Light Fastness Test Chamber unit near other heavy machinery.

tobmachine 發表在 痞客邦 留言(0) 人氣(1)

The

vacuum drying oven is designed for drying heat sensitive, easily decomposable and easily oxidizable materials. It can be filled with an inert gas, which can make some ingredients with complex ingredients dry quickly.

Scope of application:

High Temperature Vacuum drying ovens are widely used in research and application fields such as biochemistry, chemical pharmacy, medical and health, agricultural research, and environmental protection. For powder drying, baking and disinfection and sterilization of various glass containers. It is especially suitable for fast and efficient drying of heat sensitive, easily decomposable, oxidizable substances and complex ingredients.

tobmachine 發表在 痞客邦 留言(0) 人氣(0)

Although high-voltage lithium battery materials are getting more and more attention, these high-voltage anode materials are still unable to achieve good results in practical production and application. The biggest limiting factor is that the electrochemical stability window of the carbonate-based electrolyte is low. When the battery voltage reaches about 4.5(vs.Li/Li+), the

electrolyte begins to produce violent oxidation decomposition, causing the lithium-intercalation and lithium-deintercalation for the battery not working properly. The development of electrolytic liquid systems that can withstand high voltage is an important step to promote the application of this new material.

The development and application of new

high voltage electrolyte systems or high voltage film forming additives to improve the stability of electrode/electrolyte interface is an effective way to develop high voltage electrolyte. Economically, the latter is often preferred. Such additives to improve the voltage tolerance of electrolyte generally include boron, organic phosphorus, carbonates, sulfur, ionic liquids and other types of additives. Boron additives include trimethylalkanes borase, lithium borate dioxalate, lithium borate difluoroxalate, tetramethylborate, trimethyl borate and trimethylcyclotriboroxane. Organic phosphorus additives include phosphite esters, phosphite esters. Carbonate additives include fluorinated anhydryl compounds. Sulfur-containing additives include propionic acid lactone, dimethyl sulfonyl methane, trifluoromethyl phenyl sulfide, etc. Ionic liquid additives include imidazole and quaternary phosphate salts.

According to the domestic and foreign studies that have been published, the introduction of high-voltage additives can make the electrolyte withstand the voltage of 4.4-4.5v. However, when the charging voltage reaches 4.8v or even more than 5V, it is necessary to develop the electrolyte that can withstand higher voltage.

tobmachine 發表在 痞客邦 留言(0) 人氣(0)

The

battery separator plays a major role in lithium ion battery conduction lithium ions and isolation between the positive and negative electrode electronic contact. It is an important component to support the battery to complete the electrochemical process of charge and discharge.

In the use of lithium batteries, when the battery overcharge or at higher temperatures, the

separator need to have enough thermal stability (thermal deformation temperature > 200 ℃), to effectively isolate the battery positive and negative electrode contact, prevent short circuit, such as thermal runaway and even explosion accidents. Currently widely used polyolefin Separator, its melting point and low softening temperature (< 165 ℃), it is difficult to effectively guarantee the safety of the battery, and its low porosity and low surface energy, limiting the battery performance ratio. Therefore, it is very important to develop

high safety high temperature Separator.

Xiamen TOB technology research department has developed a new type of high temperature resistant porous membrane by adopting the wet process primary molding technology, which is low-cost to prepare and easy to quantify production. Preliminary study results show that thermal deformation temperature of the Separator is much higher than 200 ℃, and the thermal stability of the commercialization of non-woven Separator, can effectively guarantee the battery safety.

tobmachine 發表在 痞客邦 留言(0) 人氣(0)